our services

design and build

gages | fixtures | special machines | prototypes | tools

plastics assembly equipment

hot staking | fusion bonding | ultrasonic welding | degating | punching | stapling

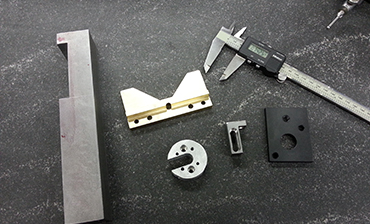

replacement details

tools | Dies | gages | production equipment | assembly fixtures

advanced diverse materials

steel | aluminum | carbide | plastics | rubber | copper | brass

Design Services

CAD | Solid Works | machine | electrical | development | reverse engineering | contract

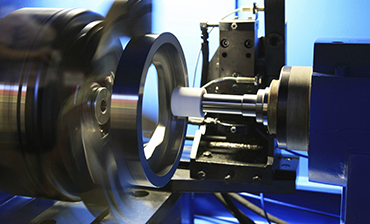

precision grinding services

surface | jig | O.D. & I.D.

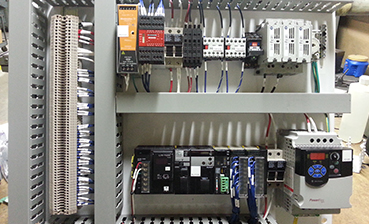

electrical & pneumatic controls

design | panel building | machine wiring

automation integration

vision systems | poke yoke | testing equipment

fabrication services

mig/tig welding | guards | machine bases | carts | racksCAD Design Services

innovative solutions

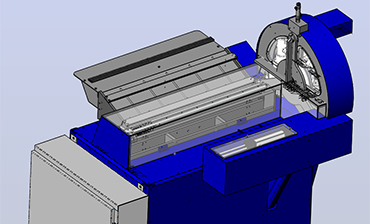

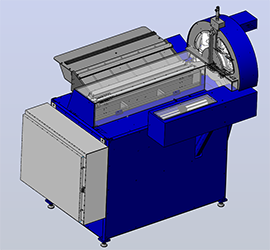

Sleeve insertion machine design

A recent project, this sleeve insertion machine was designed and built in house at LTC. Our designers use Solid Works, a popular computer-aided design software.

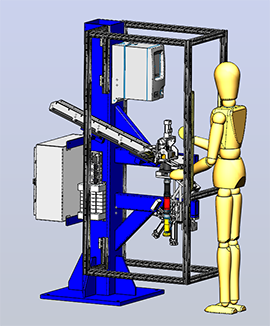

torque assembly machine design

Torque fixture designed and built in house at LTC. This machine assembles and torques a tee fitting to a sensor for an automotive emissions system. It uses a ramp feeder that feeds tees into an escarpment station. The escapement station singles out 1 tee fitting and drops it into a lock up mechanism. The operator then places the sensor into a rotating tool that threads the two pieces together and torques to the appropriate value. This machine also poke-yokes for a cross threaded sensor or an out of spec. torque.

Trust LTC for Precision Machining

Engineering & Manufacturing